It's no secret that methane gas is a major contributor to global warming, but now new space technology is helping to reduce the amount of methane being released into the atmosphere. Low-cost, satellite-based solutions for detecting methane leaks and flaring can now be used to pinpoint where gas turbines like Siemens Energy’s SGT-50 should be placed to capture and utilize excess methane for energy, hence driving decarbonization. In this blog post, we'll explore how this new technology is reducing methane emissions from oil and gas industry by rapidly deploying waste-to-gas power generators in the most cost- and energy-efficient way.

What is methane?

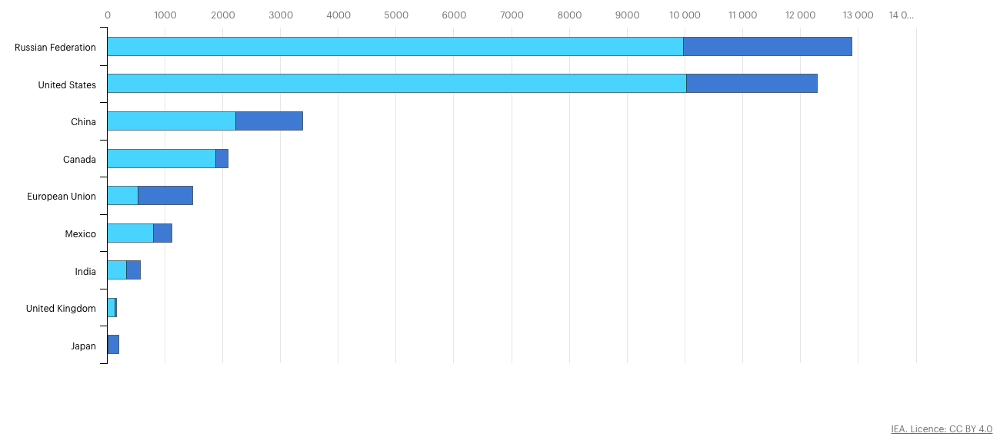

Methane is by far the most potent greenhouse gas. Atmospheric methane is largely produced by natural sources like wetlands, but also from human activities such as livestock farming and the extraction of fossil fuels. Natural gas systems, including pipelines and storage facilities, are significant sources of atmospheric methane due to leaks, or flaring which is a process where methane is intentionally burned off instead of being collected. This wasted methane can be used to generate energy if it can be properly detected and collected. Upstream oil & gas production in North America (US and Canada combined) is the #1 source of methane leaks worldwide … and the easiest to fix.

Figure 1. Oil and gas methane emissions in selected countries by sector, 2020 (IEA)

The dangers of methane leaks and flaring

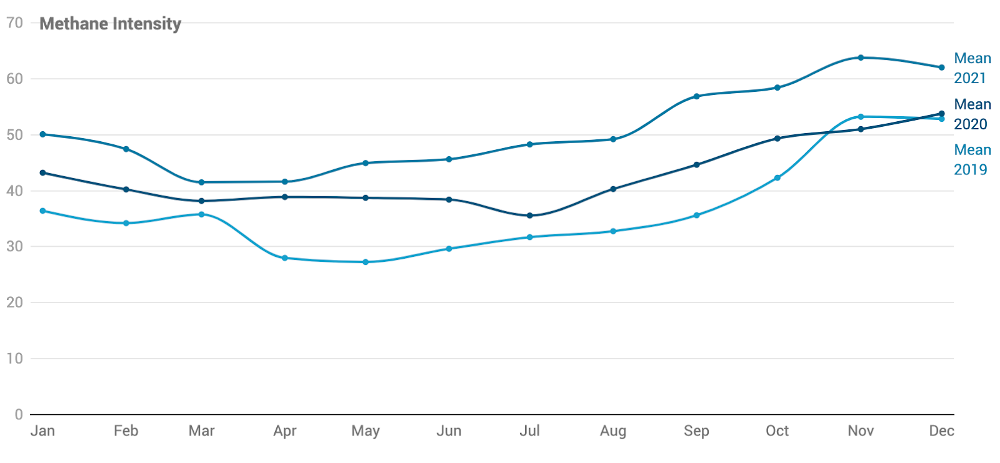

It is now widely accepted that stopping methane leaks represents the single best action we can take in the near term to avert catastrophic climate change. Unfortunately, satellite data analytics confirm that methane emissions are rising – not declining. Venting of methane – to reduce the need to flare or store excess gas – is a major source of such emissions. Such venting is often deliberate, due to lack of storage or distribution capacity.

Figure 2. Methane Intensity of Top 100 Producers Based on Satellite Direct Measurement

Flaring is also a major cause of waste and emissions. Flaring has become an increasingly common way to dispose of unwanted gas as oil production booms across the world, but it produces more greenhouse gas than burning diesel fuel. And then there are the dangers associated with flaring – on July 16th 2012 an Apache Corporation facility in West Texas released air containing high levels of sulfur dioxide and benzene due to a flaring event causing three workers to be hospitalized. From Algeria's In Amenas Gas Plant hostage crisis where dozens were killed due to intentional ignition by terrorist groups (2013) to Shell Oil's Nigeria Agbami Field incident where 20 personnel were injured when two flares ignited during maintenance operations (2016), it is clear that flaring poses significant risks – physical, economic and environmental – to those operating these facilities today.

New technology for detecting methane leaks and flaring

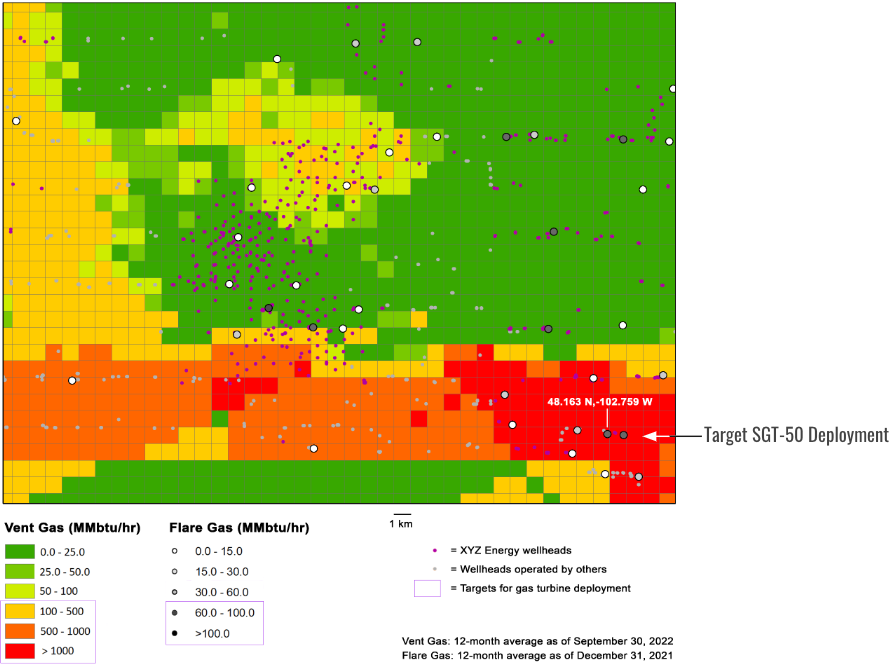

Satellite probes can now detect and attribute methane emissions and flaring at low cost. As illustrated below, these heat maps can detect high vent gas and flare gas at wellheads anywhere in the world onshore at a resolution of up to 1 km.

Figure 3. Satellite-Powered Heat Maps detect high vent gas and flare gas at wellheads. With this insight, the optimal locations for SGT-50 to capture and utilize the fugitive/excess methane can be determined cost effectively and quickly. Source: MethaneScan® by Geofinancial Analytics.

How this technology can help capture excess methane

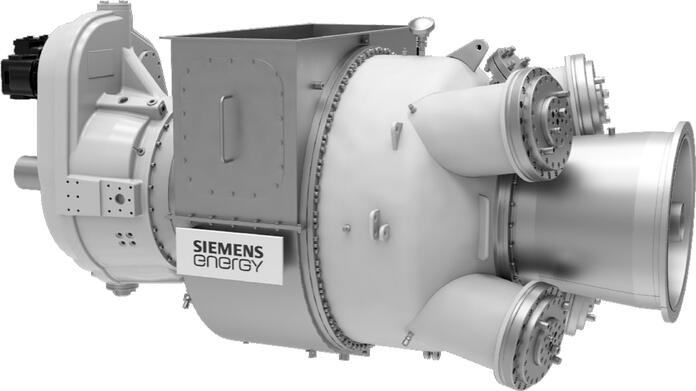

With this new satellite-based technology, it becomes possible to determine where the optimal locations are to deploy gas turbines that can capture fugitive or excess methane from oil & gas production to power anything from the production facilities themselves to data centers. For example, an upstream facility that vents or flares 50-100 MMbtu/hour of its waste gas could be an ideal location for deploying a SGT-50 unit.

Figure 4. Siemens Energy SGT-50 Turbine

In short, low-cost satellite-powered Heat Maps are ideal not only for locating fugitive emissions but also for easily identifying locations which offer excellent opportunities to capture wasted flare gas. Such locations are already prime candidates for removal of the flares and conversion to power generation without large capital investment required for “improved collection”. This enables producers to rapidly transform large flare gas sites from liabilities into assets with a clear business case.

The benefits of capturing methane for energy

Methane emissions must be cut almost in half this decade to avoid the worst effects of climate change, says the UN. If the gas wasted in flares was used to generate power, it would be enough to power the entire continent of Africa – or a substantial portion of the total power consumption of data centers worldwide. Meanwhile, external pressures for methane emissions reduction are driving demand for innovative solutions such as satellite-targeted deployment of Siemens SGT-50s as illustrated in Figure 4.

Venting and flaring at wellheads, poor equipment maintenance, leaks along pipelines and at abandoned wells, and emergency de-gassing procedures can all be avoided; however, until recently there has been little incentive to do so since methods to mitigate emissions from these practices incur operational expenses (e.g., finding and repairing leaks, methane capture, or updating outdated/broken equipment). Converting the excess methane to on-site power generation represents a win-win solution. Low-cost satellite-based detection technologies can now improve the feasibility and economics of doing so.

Figure 4. Growing external pressures are driving demand for cost-effective methane reduction solutions like use of satellite-based methane detection for smart deployment of Siemens Energy’s SGT-50 gas turbine at upstream oil and gas facilities.

Want to learn more about using MethaneScan® to reduce emissions? Contact us today!

About Geofinancial Analytics

Geofinancial Analytics® is a science-driven benefit corporation whose civic mission is to accelerate the clean energy transition by informing decisions and business practices with transparent, objective facts. Leveraging an advanced satellite-powered remote sensing platform, Geofinancial measures the greenhouse gas footprint of energy producers to drive accountability and rapid change. They are not an advocacy organization, and do not publicly shame stakeholders. They seek to inform and engage.