What is CHP?

Let’s get right into CHP and how it works.

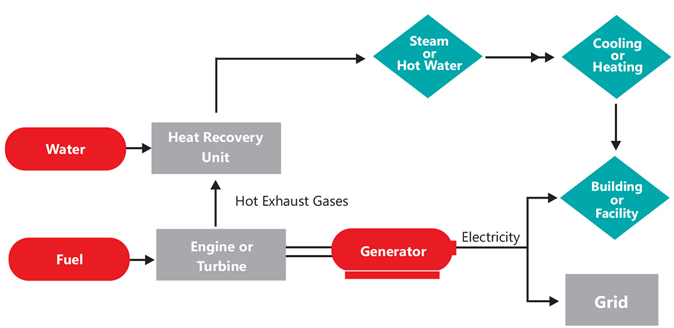

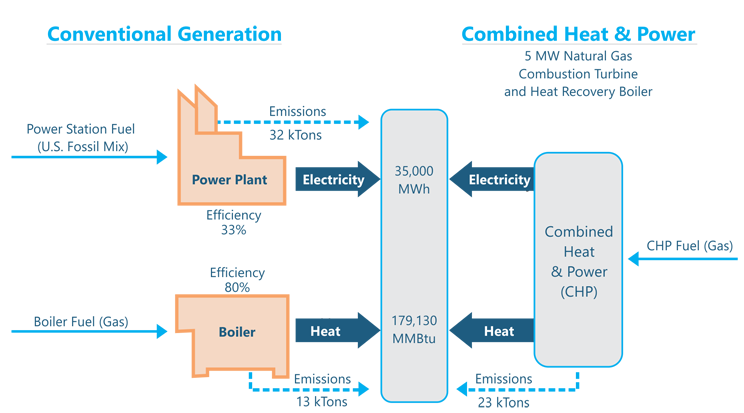

Combined heat and power (CHP) is a cogeneration process for improving the efficiency of power generation systems. When generating electricity from a conventional natural gas generator set, for example, only about 35% of the energy in the fuel becomes usable electricity. The rest of the energy, about 65%, becomes heat that is lost to the environment. With combined heat and power systems, most of that lost energy is recovered from the engine coolant and exhaust gas and converted into useful hot water or steam. This hot water or steam may also be converted to cold water through an absorption chiller - a practice known as Combined Cooling, Heat and Power (CCHP).

While historically it has been applied to large central power plants and heavy industrial sites, CHP technology is not limited to use in larger facilities. In fact, Combined heat and power systems can benefit everything from industrial businesses, to greenhouses, to government facilities to apartment buildings.

Because The cogeneration process combines the production of thermal and electric energy into one, so it requires much less fuel than traditional methods where heat and power are produced separately. This results in a much more efficient and sustainable approach to generating power; taking the place of other methods like purchasing power from the grid or purchasing a furnace or boiler.

What are the common CHP configurations?

Every combined heat and power system recovers thermal energy that is created during the production of electricity. However, there are multiple configurations that achieve this end result. The most popular configurations that harness combined heat and power technology are:

- Reciprocating engine with heat recovery unit

- Combustion turbine

- Boiler with steam turbine

Reciprocating engine with heat recovery unit

Fuel (i.e., natural gas, oil, biogas) is burned by a reciprocating engine for power generation, and excess heat is captured by heat recovery instruments. The heat is then transformed into thermal energy, which usually takes the form of hot water.

Combustion turbine with heat recovery unit

Combustion turbine or reciprocating engine CHP systems are much like reciprocating engine CHP systems, only the engine is replaced with a gas turbine and the recovered thermal energy is commonly converted to the form of high temperature steam instead of hot water.

Boiler with steam turbine

In the case of a steam turbine, steam is initially produced within a boiler. This steam is used to turn a turbine and run a generator that produces electricity. The steam that leaves the turbine can then be used to create extra thermal energy. Boiler/steam turbine systems can use several different types of fuels such as natural gas, oil and coal.

What are the benefits of CHP?

Ready for some powerful incentive to invest in CHP?

CHP is known for its unparalleled efficiency as the system is based around repurposing excess heat created during the production of electricity.

Below are the three key CHP benefits that come with using a cogeneration system compared to other conventional methods of power generation:

Reduced Costs

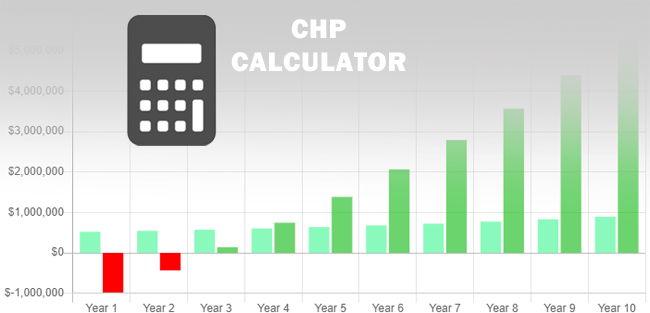

The first main benefit of using CHP is reduced costs. CHP is known for its unparalleled efficiency as the system is based around repurposing excess heat created during the production of electricity. By redirecting the heat, costs can be cut dramatically. Also, with an abundance of natural gas available, this cleaner and dependable fuel source has become a much more viable and preferred option. A simple CHP efficiency calculation can be done through T&T Power’s own CHP calculator.

Reduced Emissions

As less fuel (up to 75%) is required to produce energy, CHP emissions are significantly lower than the emissions from traditional power generation. Specifically, CHP results in lower greenhouse gas emissions as well as other air pollutants compared to other conventional methods.

Through the production of energy onsite, CHP also avoids any losses from transmission and distribution (T&D) that occur when electricity moves over power lines. By avoiding these T&D losses, CHP further decreases fuel use while helping to avoid any need for new transmission and distribution infrastructure. This also helps to mitigate congestion on the grid during times when electricity demand is high.

A Dependable Energy Supply

A dependable and continuous access to heat and power around the clock is extremely important in operating a productive and safe facility. CHP systems are resilient and supply continuous energy that allow facilities to continue running during extended grid power outages, pose few geographical limitations and can ultimately result in major cost savings. This is in stark contrast to a standby generator, which typically has a limited fuel tank and may fail to start up when needed.

The added benefit of reliability can be easily seen by examining the impacts of Hurricane Sandy, which resulted in prolonged power outages and subsequently billions of dollars worth of economic losses. CHP played a key role in keeping the lights and heat going in facilities such as hospitals, nursing homes and apartment complexes. Back-up industrial generators were not able to provide for energy demands, illustrating the resiliency of CHP systems that were in place.

Can CHP generators be connected to the grid?

When using a combined heat and power system to generate electricity and heat at a facility, operators have the option of running the generator ‘islanded’ from the electrical grid, or alternatively, in ‘parallel.’ Islanded generators are the sole source of power onsite and have no connection to the grid, while parallel generators are interconnected with the grid most of the time.

Furthermore, islanded generators eliminate dependence on the grid completely, but because they must ramp up and down to follow a variable load, they are less fuel efficient. On the other hand, parallel generators typically operate very efficiently with a fixed output to either generate baseload power for the facility, or export electricity to the grid if the local utility company will allow it. Parallel generators may also be configured to operate in island mode during power failures.

For these reasons, connecting your CHP generator to the grid is often the best choice, but in some situations ditching the grid completely in favour of generating your own power 24/7 can make sense too. That’s exactly the case for this Ontario manufacturer who was so fed up with the low quality and high cost of power available that he decided to defect from the grid entirely.

Case Study | Microgrid

4MW Industrial Microgrid

After struggling with poor power quality and rising utility rates for years, this Canadian manufacturer was ready to ditch the grid entirely, and chose T&T Power Group to develop one of Canada's first industrial Microgrids.

What are the applications of CHP?

CHP systems are used mainly in large industrial, institutional, governmental and commercial establishments where a continuous, reliable thermal and electrical power supply is essential.

These establishments could include facilities such as hospitals, retirement homes, office buildings, power plants, hotels, airports and multi-residential housing.

For example, T&T Power Group recently completed a GTA Condominium CHP Retrofit, in which two identical 32 story condominiums in the GTA sought the capability to produce their own power, and recover the heat from the installed engines to supply domestic hot water to the building. After a thorough CHP feasibility study, this project was executed as a zero-capital Power Purchase Agreement (PPA) and has since reduced the condo’s energy costs while also improving resilience.

T&T Power Group utilized the power of CHP in another recent project with a commercial cannabis grower in Ontario. T&T Power Group’s CHP solution ensured that reliable and efficient power would be provided to the greenhouse in an eco-friendly manner. This recent project highlights the practicality of CHP systems for cannabis greenhouses.

Luckily, small and medium-sized businesses in Ontario are also able to benefit from CHP systems. While large businesses can cut the cost of their electricity in half by participating in the Industrial Conservation Initiative (ICI) to mitigate the province’s Global Adjustment fees associated with the 5 peaks in Ontario, thousands of small and medium sized business cannot similarity benefit from the ICI. Instead, these smaller power consumers can capitalize on spark spread and generate their own lower-cost power behind the meter using a CHP generator.

Case Study | Combined Heat & Power

Condominium Retrofit

This installation for two condominium complexes created cheaper power, free hot water and significant savings that will only continue to grow.

Case Study | Combined Heat & Power

Cannabis Greenhouse

Upgrading a greenhouse operation to produce their own power while modernizing their facility, creating electrical redundancy while enabling future expansion possibilities.

Why is CHP such a good fit for Greenhouses?

Greenhouses - especially those with lighting installed - require a lot of electricity, heat and CO2. CHP generators can generate all three of these components on their own, as opposed to acquiring electricity from the grid, heat from a boiler and CO2 from a delivery company/CO2 burner onsite.

To learn more about how CHP will provide power where utilities cannot, generate electricity for less than $0.10/kW per hour, lower carbon emissions and more, check out T&T Power Group’s webinar in partnership with Siemens Energy.

There are numerous other advantages from CHP as a greenhouse owner/operator including lower energy costs, energy security and emission reductions. Another huge benefit is the efficiency of combined heat and power, which can be over 90% in certain facilities.

A further benefit is the potential for an absorption chiller to convert hot water into cold water. In the case of indoor cultivation facilities where cooling is typically in much higher demand than heat for climate control and dehumidification purposes, the hot water recovered from the CHP generator can be fed into an absorption chiller to provide a constant supply of cold water.

Case Study | Combined Heat & Power

DT Enterprise Farms

A greenhouse held back by a crucial power problem, when Ontario hydro did not have enough infrastructure to supply the electricity needed for expansion.

What does the future of CHP look like in Canada?

Historically, solely large industrial facilities considered CHP for power generation in Canada. In fact, most of the CHP systems in use today were implemented by large industrial facilities during the late 1980s through the early 2000s - when CHP offered savings due to policy incentives like Ontario’s Feed-in-Tariff (FIT) program.

A wide range of industries are starting to adopt CHP systems, including smaller commercial facilities.

But today’s CHP market is extremely different. A much wider range of industries are starting to adopt CHP systems, including smaller commercial facilities. Many of the reasons behind this shift are due to the various benefits associated with CHP systems, but there are several other factors at play.

Fortunately, CHP installations have been made simpler in recent years. Design and installation used to necessitate customized engineering, but standardized packaged CHP systems are now available - thus eliminating the time, effort and stress generally involved with the design-build process. This approach reduces CHP installation costs, which has become a key driver of continued usage. In short, CHP operation and maintenance has become a much more simplified process for even the smallest of businesses.

Which fuels can power CHP?

Although natural gas CHP systems are the most common, CHP technology is fuel-neutral, meaning renewable fuels such as biogas and wood waste are also used in cogeneration systems. Boiler/steam turbine systems, as mentioned earlier, can use almost any kind of liquid, gas or solid fuel but typically rely on low cost solid or liquid fuel. As such, these CHP configurations mainly use natural gas, oil, biomass or coal.

CHP systems can use a variety of fuels that are capable of achieving energy efficiencies of over 70%

CHP systems can use a variety of fuels that are renewable or fossil-based, and are capable of achieving energy efficiencies of over 70 percent. This figure is in relation to separate heat and power generators which are an average of 45 percent efficient.

What is the difference between standby power and CHP?

It’s useful to understand the key differences between standby power and cogeneration power. Standby power refers to the backup power source homes or facilities rely on during an electrical grid power outage. In the case of a power outage, this is when the standby or emergency generator would switch into action.

Commercial standby power, typically achieved through a large standby generator or industrial size generator, provides an automatic transition from the utility power to an on-site generator keeping organizations productive, investments secure, and people comfortable.

CHP systems, on the other hand, replace or supplement electricity provided from local utility providers and convert excess heat to thermal energy as a bonus. An industrial size CHP generator serves not as a backup power source but as the prime power generation in a facility.

Does CHP work in Canada?

The utilization and economic success of CHP in Canada varies based on each province. For example, in provinces Ontario and Alberta, the cost of electricity is extremely high compared to that of British Columbia. As such, facility operators in British Columbia would not be able to realize the same economic benefits as facilities in Ontario or Alberta from adopting CHP technology.

That said, the decision to purchase a CHP generator needs to take into consideration the cost of electricity within the province, in addition to the cost of cogeneration itself.

T&T Power Group’s CHP savings calculator is a great tool to see the impact of utility prices on the return on investment (ROI) of a CHP project.

How does CHP impact the environment?

Our planet Earth is "Team CHP" all the way. As less fuel is burned to produce each unit of energy compared to traditional electricity and heat supply, cogeneration technology decreases greenhouse gas emissions (such as carbon dioxide and sulfur dioxide) and other harmful pollutants. Additionally, by capturing excess heat that is created in the production of electricity, CHP requires less fuel to generate the same amount of energy.

CHP generators are suitable solutions for groups that are committed to the environment and to sustainable power generation. Cogeneration has already been adopted by parties such as fire stations, schools, hospitals and other health facilities. CHP is perfectly suited to deal with the energy constraints of these types of facilities - and our team at T&T Power Group can build a custom solution that fits any requirement.

The broader environmental impact relating to CHP emissions is a key reason why the technology is being embraced by more and more industries.

How long does a CHP generator last?

Unlike standby generators which could run anywhere between 1-100 hours per year, a CHP generator is designed to carry electrical loads 24/7, for 8,000 or more hours per year.

When serviced by a capable CHP maintenance company, owners can expect 6-7 years of continuous operation from a Siemens gas engine in a CHP generator before considering a major overhaul. Once this overhaul is completed, the lifespan of the CHP generator essentially resets, and owners can expect another 6-7 years of continuous operation. T&T Power Group’s CHP generator sets can be overhauled repeatedly, extending the engine’s lifecycle for as long as desired.

How much does a CHP generator cost?

CHP installation costs have dropped dramatically over the years, increasing the accessibility of the systems for businesses of all sizes. The capital requirements for a CHP generator however are still much higher than a conventional emergency standby generator due to the extreme duty and longer life expectancy. Due to the lower hours of operation, standby generators are quite affordable and are a suitable fit for more conventional leasing and financing options.

The cost of a cogeneration unit through conventional financing options would require a large down payment and monthly payments, so business owners may opt to finance projects through a Power Purchase Agreement (PPA). A PPA allows the operator to circumvent ownership of the equipment and simply purchase the desired electricity per-kW-hour, at rate lower than they would have paid through their local utility company.

Does CHP work for my home?

Now let’s talk residential CHP systems, or micro CHP. In order to determine whether a CHP system (of the micro variety) would be ideal for your home, there are some key factors to consider.

First and foremost, if you’re living in a small to medium-sized home (or anything under approximately 3,000 square feet), CHP might not be for you. Micro CHP systems are best suited for larger or luxury houses with high electricity costs or thermal loads (including various amenities such as hot tubs or heated pools). Even when using a lower-cost fuel source like natural gas, powering a private residence with CHP would have a very long payback period, if any at all.

For that reason, Micro CHP systems are a great solution for homes that are located in remote areas - especially if they’re subject to extreme weather conditions that could result in prolonged outages. In such cases, a micro CHP system can keep the lights on and your house warm indefinitely during any unexpected blackouts.

Does CHP make sense for my facility?

Ensuring that an investment in CHP does indeed make sense for your particular facility and its operations in the first place is the first crucial step.

Typically, larger facilities will see the greatest return on investment if they choose to implement a CHP generator. However, CHP is a good choice for any facility that consistently has an electrical load of at least 300 kW, as well as use for hot water or steam.

If your facility depends on a constant electrical and thermal demand of this scale, CHP would likely be an efficient method of supporting your continuous load. To see a CHP payback calculation for your own operations, feel free to use T&T Power Group’s very handy CHP calculator.

The emergence and continued usage of CHP underscores a promising time for electric power generation – as power providers have been listening to the customer’s growing demand for more eco-friendly, cost-effective and resilient power generation.